Vertically Integrated

Redefining Efficiency

Our broad-reaching capabilities allow us to manage all aspects of our manufacturing process in creating leading-edge photonics solutions.

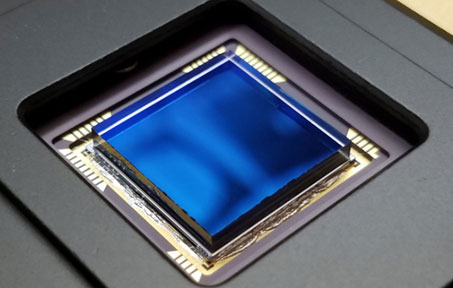

Imaging & Sensing Solutions

Spectroscopy, Hyperspectral, Multispectral

Providing systems and services, including custom camera development, OEM Spectrometers, coverglass & micro lenses removal, and custom electrical components.

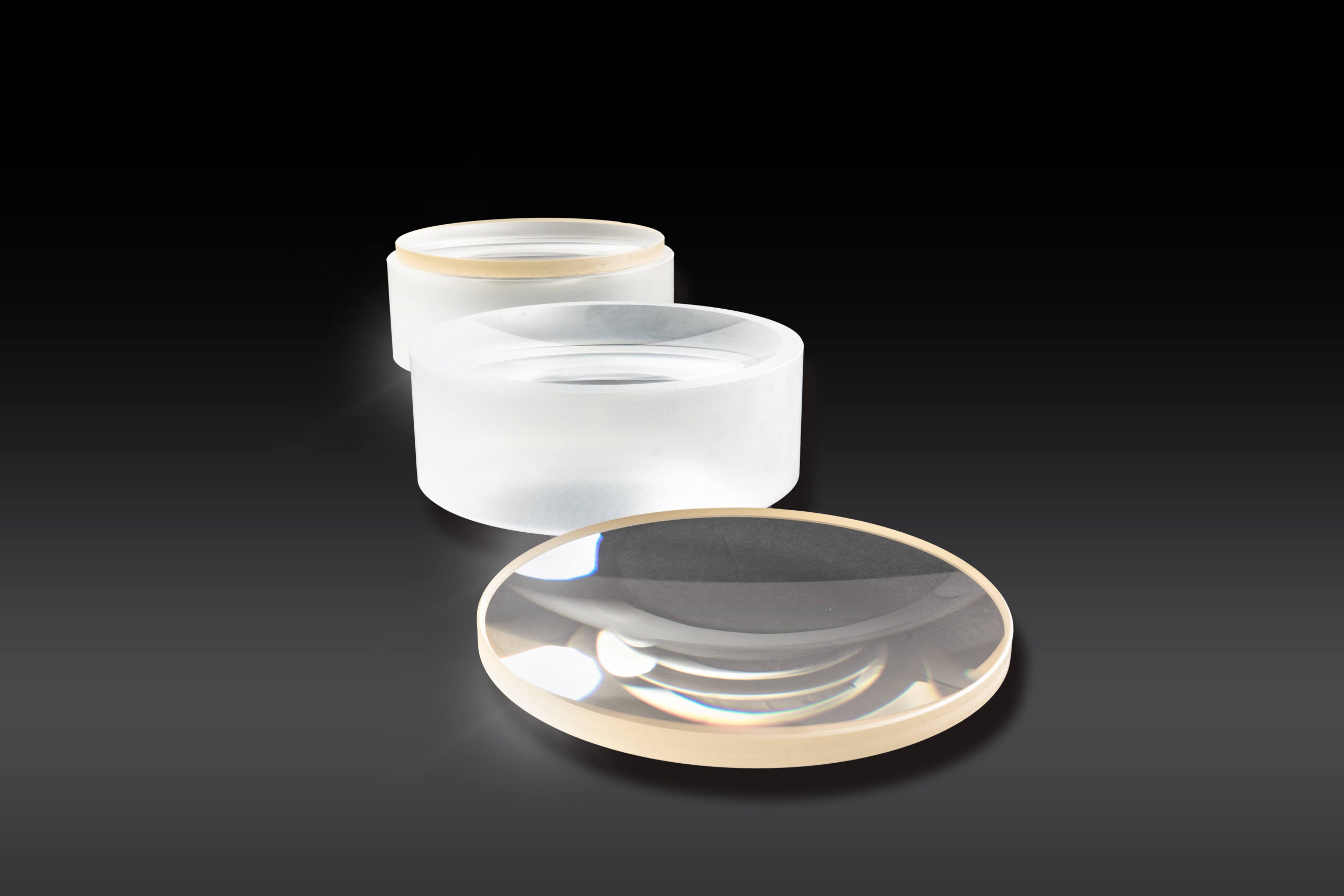

Optical Components & Assemblies

Precision optics for prototype and production

Diverse fabrication and coating capabilities to produce optics and opto-mechanical assemblies.

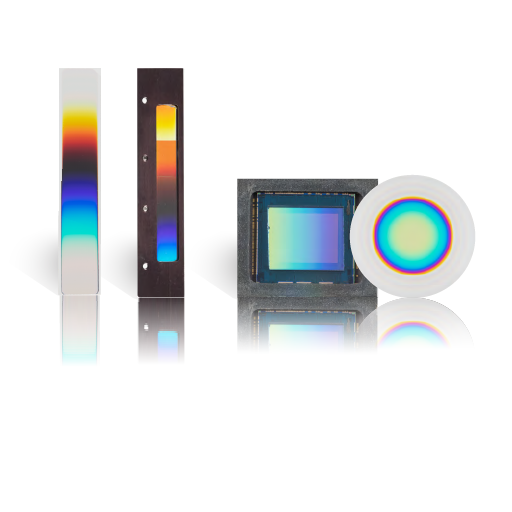

Optical Filters Made Easy

Our specialty is precision optical coating

Leaders in custom coating and lithography offering off-the-shelf and specialty filters.

Salvo Technologies advances photonics technology through innovation and vertically integrated manufacturing. We specialize in optical components & assemblies, multispectral and hyperspectral imaging systems, spectroscopy & point detection systems, electronics design & integration, and surveillance & defense solutions. We serve the medical, industrial, agriculture, aerospace, defense, and consumer markets by delivering high-precision quality products with a commitment to on-time delivery. With our employees’ knowledge and vast experience, we have the tools to help our customers succeed from design to development to integration.

Industries

Salvo Technologies provides an integrated suite of technologies to serve a broad range of markets.